OSB Oriented Strand Board Production Process

OSB (Oriented Strand Board) is a board made of wood chips and adhesives by hot pressing.

The production process mainly includes the following steps:

Raw material preparation: Select suitable wood, usually coniferous trees, for chipping and drying.

Orientation: Arrange the chips in a specific direction to enhance the strength and stability of the board.

Adhesive coating: Apply an appropriate amount of adhesive evenly on the wood chips, usually using environmentally friendly glue such as urea-formaldehyde resin.

Forming: Put the arranged wood chips into the mold and apply pressure to form a preliminary board.

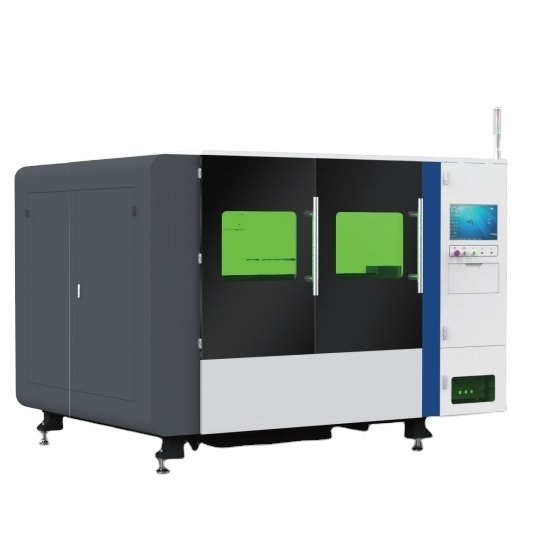

Hot pressing: Hot pressing is carried out under high temperature and high pressure to cure the glue and shape the board.

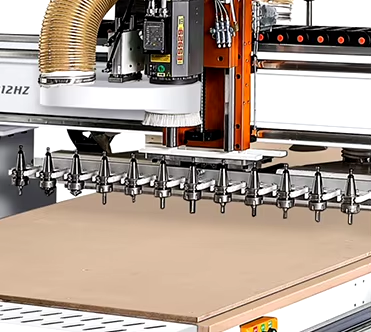

Cooling and trimming: Cooling after hot pressing, then cutting into the required size, surface treatment and inspection.